Ready-for-use TIA Portal

TIA Portal example project for S7-1500

(S7-1511 and KTP700 Basic or MTP700 Unified Comfort) in

German, English, French, Spanish and Italian consisting of HMI visualization and WP321 function block (multiinstance ability).

7MH4138-6AA00-0BA0

SIWAREX WP321 WEIGHING ELECTRONIC (1 CHANNEL) FOR STRAIN GAUGE

LOAD CELLS / FULL BRIDGES (1-4 mV/V) FOR SIMATIC ET200SP, FITS to

BU-TYPE A0, RS485- INTERFACE FOR CONNECTION OF SIWATOOL OR A REMOTE

DISPLAY Detailed load cell diagnostics possible with digital junction

box SIWAREX DB (7MH5001-0AD20 or 7MH5001-0AD0

The .zip-file includes the following components:

- TIA Portal V15.1, V16, V17 and V18 project with SIWAREX WP321 – KTP 700 Basic

- TIA Portal V15.1, V16, V17 and V18 project with SIWAREX WP321 and SIWAREX DB – KTP700 Basic

- TIA Portal V17 and V18 project with SIWAREX WP321 and SIWAREX DB - MTP 700 Unified Comfort

ATTENTION:

STEP

7 V17 Update 4 and Unified Panel Image and/or Unified Runtime V17

Update 4 is required to use the Project including the MTP 700 Unified

Comfort Panel.

TIA Portal example project for S7-300 and

S7-400

(S7-315-2 PN/DP and TP700 Comfort or KTP700 Basic)

in German, English, French, Spanish and Italian consisting of HMI

visualization and WP321 function block (multiinstance ability). Please

use / copy the function

block included in the project for all other CPU of the 300 and 400

series as

well.

The .zip-file includes the following components:

- TIA Portal V15.1, V16, V17 and V18 project with SIWAREX WP321 – TP 700 Comfort

- TIA Portal V15.1, V16, V17 and V18 project with SIWAREX WP321 and SIWAREX DB – KTP700 Basic

========================================================================================

Ready-for-use-small TIA Portal

TIA Portal example project (S7-1511 and KTP700 Basic) in

German, English, French, Spanish and Italian consisting of HMI

visualization and WP321 function block (multiinstance ability) with

lower memory demand. This function block has the the data records 3, 6,

10 and 14 available only, which allow the commissioning of the scale,

the definition of the limits, as well as the selection of the process

values read by cyclic I/O communication.

All further data

records, as well as the advanced error message system and the

multiplexed commands 1, 2 and 3 are not available by this type of

function block!

The .zip-file includes the following components:

- TIA Portal V13 SP1, V14, V15, V15.1, V16, V17 and V18 project with SIWAREX WP321 – KTP 700 Basic

Download (36,6 MB)

Download (36,6 MB)

========================================================================================

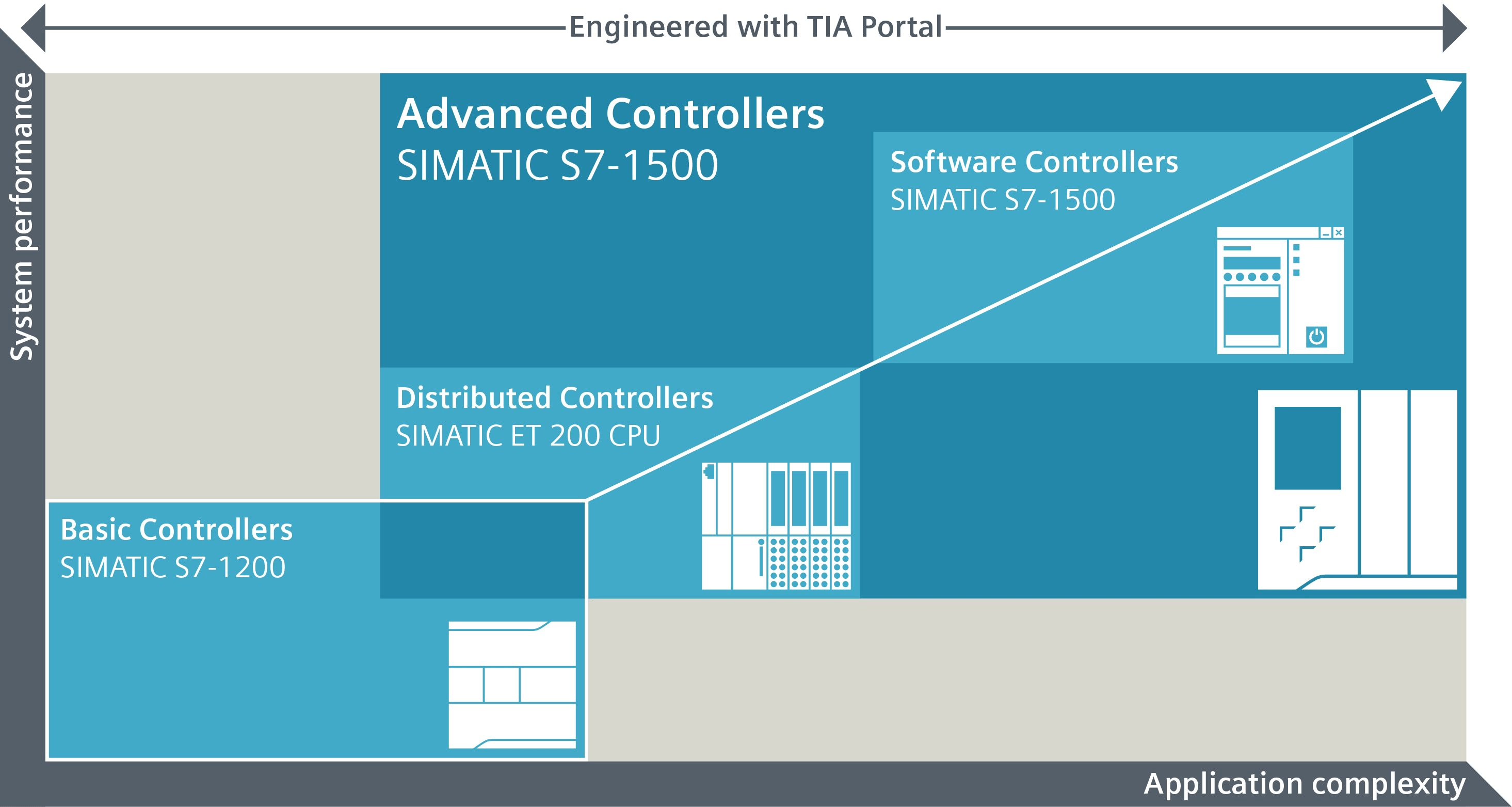

Library TIA Portal

TIA Portal V13, V14, V15, V15.1, V16, V17 and V18 global block

library with all available WP321 function blocks for S7-1200, S7-1500

and S7-Software Controller

ATTENTION: It’s important to choose the right project/library relating to the CPU firmware version!

Download (24,4 MB)

Download (24,4 MB)

========================================================================================

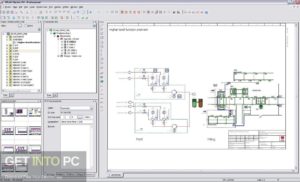

Ready-for-use SIMATIC Manager

The S7-Classic project includes a ready-to-use project with a SIWAREX

WP321 connected to a CPU 315-PN/DP and a HMI with WP321 function block

(multiinstance ability). Please use / copy the function block included

in the project for all other CPU of the 300 and 400 series as well.

The .zip-file includes the following components:

- Simatic Manager V5.5 SP4 project with SIWAREX WP321 and KTP600 (WinCC flexible 2008 SP3)

- Simatic Manager V5.6 SP2 project with SIWAREX WP321, SIWAREX DB and KTP 700 (TIA Portal V15.1)

Download (3,4 MB)

Download (3,4 MB)

========================================================================================

Ready-for-use-small SIMATIC Manager

The Simatic-Manager project-archive (SIMATIC Manager V5.5 SP4 is

required) includes a ready-to-use project with a SIWAREX WP321 connected

to a CPU 315-PN/DP and a HMI (KTP600 Basic) with WP321 function block

(multiinstance ability) with lower memory demand. This function block

provides access to the data records 3, 6, 10 and 14 only, which allow

the commissioning of the scale, the definition of the limits, as well as

the selection of the process values read by cyclic I/O communication.

All further data records, as well as the advanced error message

system and the multiplexed commands 1, 2 and 3 are not available with

this type of function block!

Download (3,9 MB)

Download (3,9 MB)

========================================================================================

TIA Portal example project to program several SIWAREX WP321 in one project.

The

TIA Portal Project is based on the example project for S7-1500 in

German and English, it has been developed in order to connect several

scales to a 1500-CPU or 1200-CPU which is connected to a panel. This  document (2,2 MB) describes the procedure.

document (2,2 MB) describes the procedure.

The .zip-file includes the following components:

- TIA Portal V15.1, V16, V17 and V18 project with SIWAREX WP321 – TP 700 Comfort

Download (30,8 MB)

Download (30,8 MB)

========================================================================================

TIA portal library for Siwarex WP321 to limit the simultaneously use of system function data record read and / or write

The

library is created for 1200 and 1500 CPU’s. The function block

“WP321_Token” is an extension of the “WP321_Multiplex” getting started.

This  document (568,9 KB) describes the procedure.

document (568,9 KB) describes the procedure.

Download (228,3 KB)

Download (228,3 KB) WinCC_TIA_Portal_Ethernet_Transfer_en.pdf ( 758 KB )

WinCC_TIA_Portal_Ethernet_Transfer_en.pdf ( 758 KB )