Plant Asset Management systems let you squeeze more out of your industrial equipment by reducing unplanned stoppages and unnecessary maintenance tasks. Estimated savings in the U.S. could exceed $60 billion.

Wouldn’t it be nice to know something was going to break before it actually brought your production line to a grinding halt, killing productivity, throwing off schedules and possibly compromising delivery deadlines? Now think about how nice it would be to be able to put that precognition to use and apply a little predictive maintenance to not only keep things running smoothly, but to keep them that way for longer before having to replace expensive equipment.

This is the promise made by Plant Asset Management (PAM) systems.

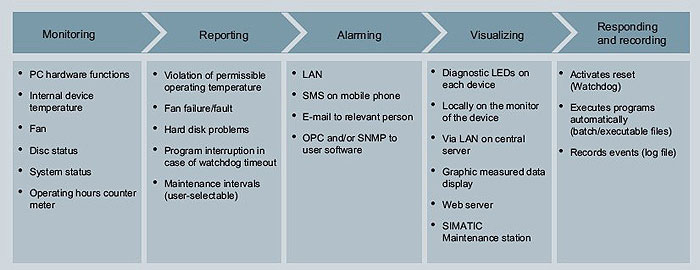

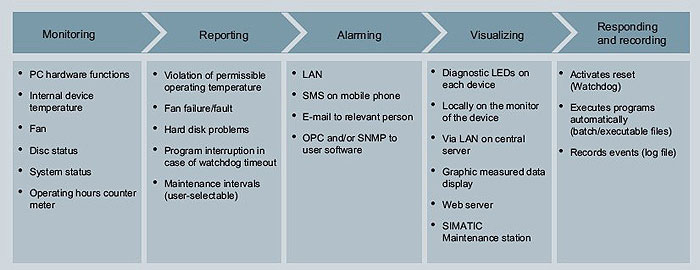

PAM systems provide timely information to help maintenance and operations improve asset availability, reducing the time required to maintain equipment and optimizing their efficiency. PAM systems rely on a combination of diagnostic software and hardware tools that perform automatic, real-time monitoring and alarming of asset-related key performance indicators. If something starts to fall out of acceptable parameters – such as a pump starting to vibrate more than it should – you are notified and can take predictive rather than preventative or corrective action. “Many people think PAM is a maintenance function, and it is that, but it’s also much, much more,” says Chuck Cotton, a spokesperson for Siemens Energy & Automation where he is deeply involved with the company’s PAM offering. “PAM enables you to squeeze a lot more blood out of your rocks.

“In addition to a higher return on assets,” he adds, “you can reduce the number of unscheduled stoppages, you can react more quickly when you do get a disruption that translates into a lower mean time to repair, you get decreased maintenance costs and ultimately improved productivity out of your plant and improved ROI from your assets.”

With many manufacturing operations freezing capital investments until the economy rebounds, it has never been more important to get more out of your existing investments, a contributing factor to remarkable market growth for PAM solutions.

According to Wil Chin, a research director who follows PAM at ARC Advisory Group in Dedham, Mass., the global market for PAM systems grew by an average of more than 13 percent a year since 2006, eclipsing the forecast of 10.8 percent.

“Today’s PAM systems offer end users a solution appropriate for both good and bad times,” says Chin, the primary author of the recent PAM study, Plant Asset Management Systems Worldwide Outlook. “The value proposition for PAM systems remains intact and – when combined with safety and other drivers associated with the decline in the workforce – PAM adoption will not fall off nearly as much as other automation investments.”

Chin believes that this resiliency is founded on PAM’s ability to help manufacturers do more with less. “By providing information at the right time and in the right context, workers work smarter.”

Despite this prediction, things are not necessarily all rosy for the PAM vendors.

“End users understand that PAM can help them to predictively diagnose the health of critical assets, but don’t always make the connection to how this can help improve profitability when resources are scarce and demand for their products is declining,” says Chin, who adds there is still a lot of confusion around PAM systems for end users and even where there is a clear understanding a deployment requires significant domain expertise. “Suppliers and end users need to educate themselves about the benefits that PAM systems offer to help them survive the economic contraction.”

That said, the impact can be profound.

In his book An Introduction to Predictive Maintenance, Keith Mobley claims that, depending upon the industry, maintenance costs can run anywhere from 15 to 60 percent of the cost of goods produced. He also suggests that up to a third of all maintenance expenditure is wasted because of poor or unnecessary maintenance. When he wrote this book in 2002, he estimated this translates to a loss of more than $60 billion per year in the United States.

“Predictive maintenance is really the ideal since it schedules specific tasks when they are actually required by the equipment rather than when someone estimates they will be required,” says Cotton. “Preventative maintenance, on the other hand, is about scheduling work whether it’s needed or not based on hours of operation or number of operating cycles. This leads to equipment being replaced while it still has some life left and pulls your skilled human assets off other more productive tasks.”

In the past, operations and maintenance teams have each had their roles to play in helping companies get the most out of their plants, but they have traditionally come at the problem separately. PAM brings them together, unifying and organizing their efforts.

“Traditionally, the maintenance organization was primarily concerned with asset availability, while operations was most concerned with asset utilization,” says Cotton. “These two functions are often at odds with each other. PAM enables you to manage both these factors in a holistic manner, which is more effective from a strategic business perspective. PAM systems provide the intelligence required to help you balance asset availability with asset utilization, helping you get the maximum possible productivity out of your plant.”

Getting started with a PAM strategy isn’t as complicated as it may seem. There is no need to launch into a plant-wide revolution right away, says Cotton. “Start with a criticality analysis. Look at what has the most impact on environment, production and safety. Start small, focus on a couple of projects, then expand, hopefully, to plant-wide strategy.”

At the core of any PAM strategy, adds Cotton, is integration. “It is important to integrate all the major components so they can be monitored and you can draw meaningful diagnostics from them. At Siemens, our Totally Integrated Automation approach delivers these elements – tying all the individual pieces together through networking then providing simple visualization and alarming through HMI tools, ultimately giving you more control over your operations.”

For further information on products within the Siemens Totally Integrated Automation approach, please click

here.

Production and storage process in food industry are subjected to specific laws related to quality control; the quality control system based on the Winlog Pro software SCADA platform has been successfully applied in many sectors of food industry; actually it gives the possibility to comply with requested quality control criteria limiting both the investment cost and the production loss due to the installation of the system.

Production and storage process in food industry are subjected to specific laws related to quality control; the quality control system based on the Winlog Pro software SCADA platform has been successfully applied in many sectors of food industry; actually it gives the possibility to comply with requested quality control criteria limiting both the investment cost and the production loss due to the installation of the system.

When Siemens introduced Sinumerik in 1960 as the industry’s first numerical control (NC), customers immediately realized a dramatic improvement in their productivity and flexibility. These end user benefits helped put Siemens on the map and provided a foundation that helped vault the company to the pinnacle of the mechanical engineering industry. Now celebrating its 50th birthday, the latest evolution of Sinumerik still delivers customer value making it one of the longest serving brands in the world.

When Siemens introduced Sinumerik in 1960 as the industry’s first numerical control (NC), customers immediately realized a dramatic improvement in their productivity and flexibility. These end user benefits helped put Siemens on the map and provided a foundation that helped vault the company to the pinnacle of the mechanical engineering industry. Now celebrating its 50th birthday, the latest evolution of Sinumerik still delivers customer value making it one of the longest serving brands in the world.